Behind every great beer is a great process.

Brewery automation has grown with the American craft beer industry to save time and money while enhancing quality.

But there’s some tension when it comes to automation in craft breweries.

Craft brewing has been regarded as a unique blend of art and science dating back thousands of years, and now the industry is changing for modern times. To brew beer at an accelerating rate and keep up with sales, human experts need to step back and let automation do much of the job.

This leads brewers to ask: Is the romance lost when machines take over?

Here, we’ll discuss both the essential machines operators rely on, and the steps that preserve brewing as a work of art.

The Machines

The degree of automation often depends on the size of the craft brewery.

For all sizes, consistency is a primary goal. Fewer brewers always leads to higher consistency because there’s less chance for human error. In smaller breweries, consistency comes with the nature of the job as a limited number of refined experts have control over the process. But as breweries grow, automation enters the picture to maintain this consistency and reduce how many hands touch the product.

Luckily, we were able to hear from the whole spectrum around our local Philadelphia region, including:

- Victory— James Gentile, Brewery Manager

- Yards— Frank Winslow, Director of Quality Assurance

- Sly Fox— Brian O’Reilly, Brew Master

- Free Will— David Bergey, Plant Manager

- Saint Benjamin— Tim Patton, Brew Master and Owner

- Evil Genius— Luke Bowen, Founder

While interviewing these experts and visiting their facilities, we paid special attention to a number of unique solutions from controlling steam to lifting kegs.

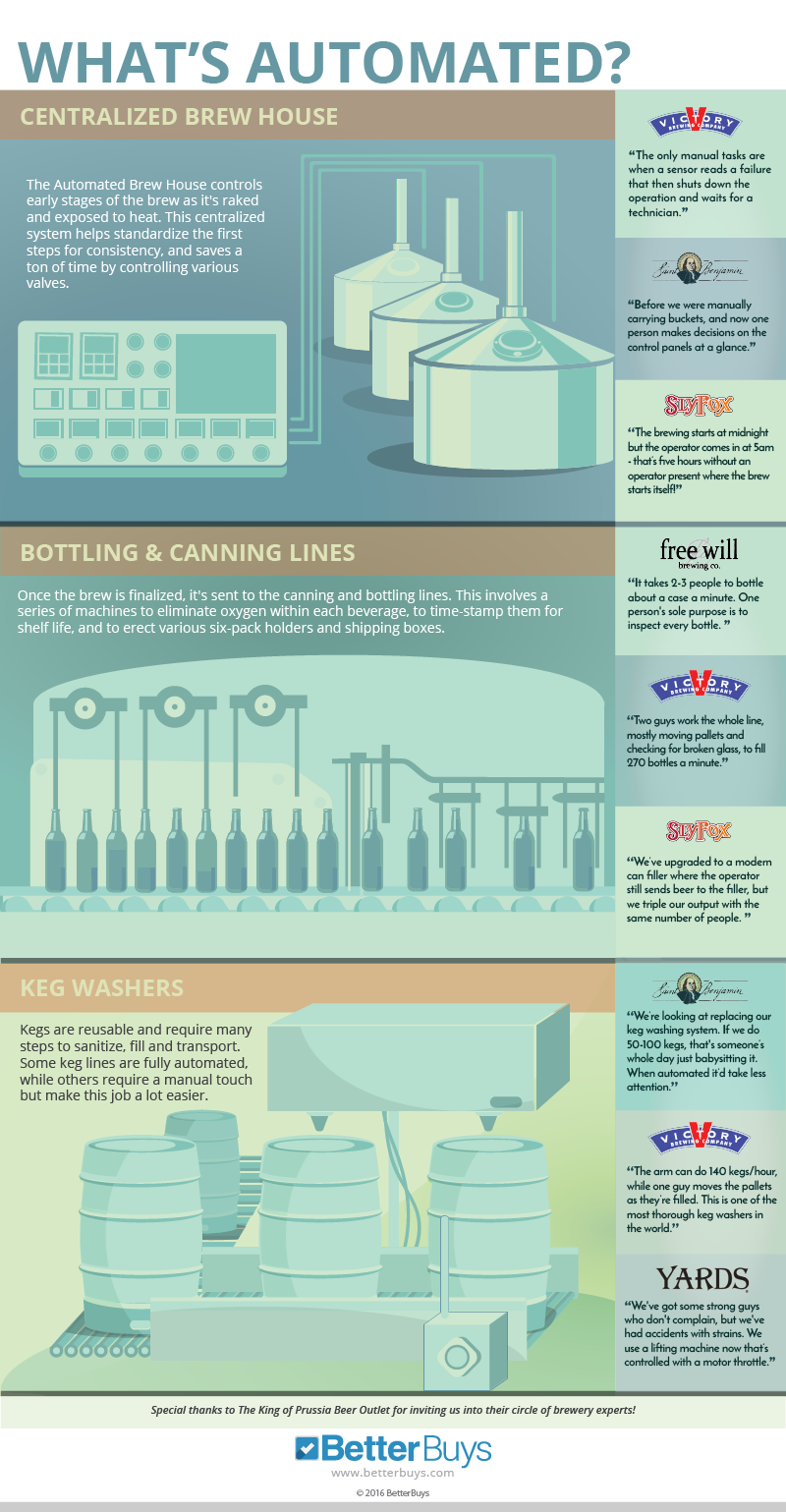

We were able to pinpoint the three most automated processes:

There was one other process that we found to be consistently automated.

Bright beer is highly refined beer. To make this, breweries either rely on a centrifuge or a DE Filter. Special brews go through this process for the ultimate quality and consistency.

Frank with Yards described to us exactly how a DE Filter works:

Most breweries you’ll find use Diatematious Earth (DE)– it’s fancy dirt collected with specific sized particles of fossilized skeletons. You’re basically creating a filter bed using the earth. It’s a fine powder with smaller pieces on top and the particles work their way through. Its smaller than a micron and its not a solid state. You filter down to a fairly high level of clarity. We use a Horizontal DE Filter.

James with Victory showed us their Parkesburg brewery’s centrifuge, which is an incredibly loud room, and later described the process:

The Centrifuge is entirely automated to clear solids by rapidly spinning. Everything is calibrated to create bright beer according to very high clarity standards that eliminate certain yeast. There’s a bigger one, then a smaller one, and a final filter. Humidity, timing, and recipe parameters are all automatically taken into account.

It’s worth noting that while Victory is known for it’s high clarity standards, all of Yards’ brews are gluten free. Breweries have a choice to send brews through different clarity processes, and many are still evolving to find the right consumers.

What About Maintenance?

All machines require maintenance — especially those central to a production line.

When a facility suffers from down time it affects the entire business. And in food and beverage industries where perishables are involved, reliability must be a key focus.

As Luke with Evil Genius eloquently put it:

Liquid in, liquid out—You gotta streamline the process so that less beer goes on the floor.

Here’s a rundown of how these breweries conduct maintenance:

- Preventive Schedules: A calendar-based system establishes a daily, weekly and monthly routine for when it’s time to maintain equipment. This is to prevent the machine from ever having an issue.

- Predictive Maintenance: When metrics are gathered over time, the maintenance team can accurately predict when its time to replace various parts. This is very helpful for balancing inventories.

- Condition-based Alerts: Alerts and triggers are in place to read real-time conditions, such as temperature and pressure, and can halt operations if something goes wrong.

- Yearly Check-ups: The machines’ manufacturers typically visit the breweries and assess machines once a year.

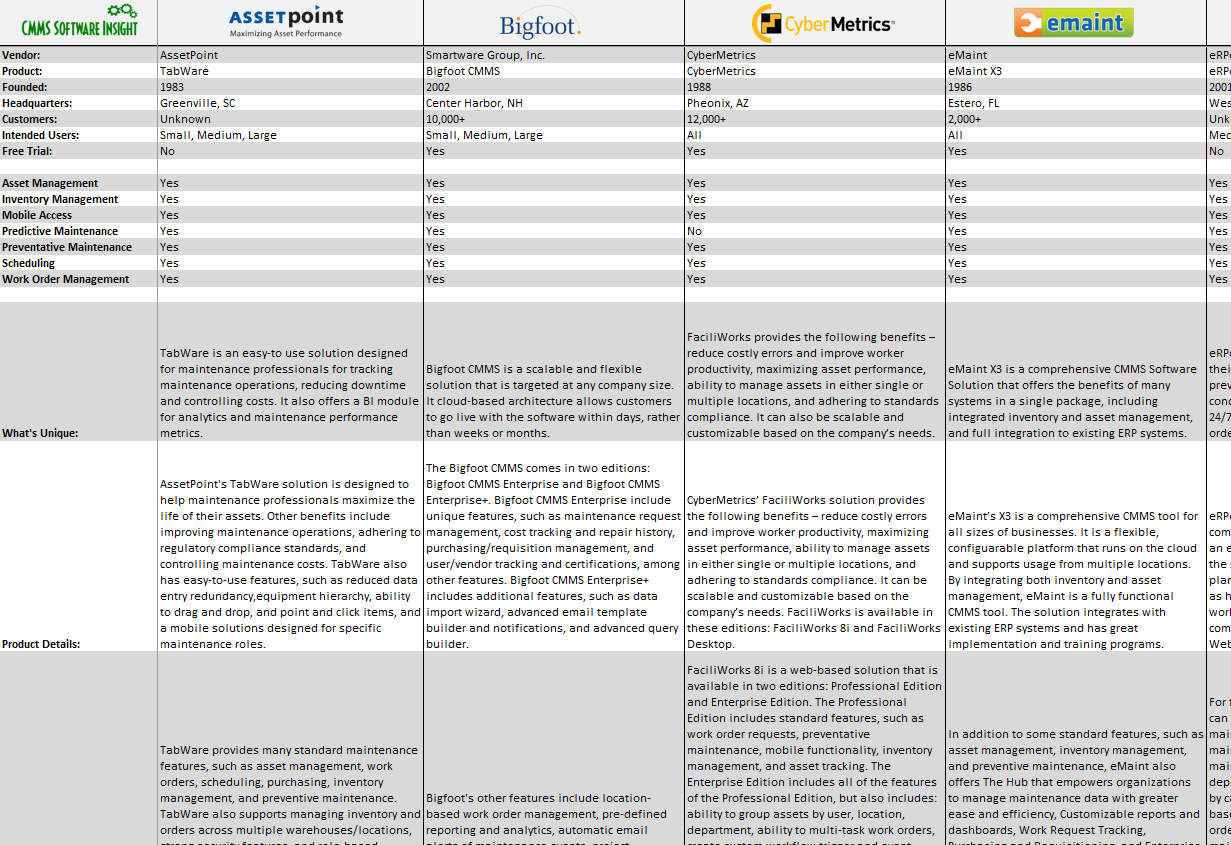

To organize and execute maintenance tasks we found technicians either use a series of Excel sheets, custom-built software, full Enterprise Resource Planning (ERP) systems, or the most common option, a Computerized Maintenance Management System (CMMS).

CMMS is a scalable software solution for managing work orders, technician schedules, and various documents such as warranties, receipts and contracts. There are many CMMS vendors available, including those that offer mobility for technicians to access maintenance data from the palms of their hands.

Yards is an example of a brewery that doesn’t use a specific software solution for this process, but Frank described to us how they achieve the same maintenance standards their own way:

We do preventive and predictive maintenance our own way. A best example is the crowning process in our bottles. We measure the crimp on caps and look for changes and drifts from our spec, and if it shifts to be too tight or too loose then we re-evaluate that and run some tests. We track the wear and tear – the intensity in which the crown is put on the bottle to press the bottle, and some wear parts within that. If we see variation that’s one thing we would look into adjusting. We either change how hard it’s coming down or we need to change out the centering bell parts. Same can be said for fill heights in the bottles. We would love to have software for it.

One other unique solution we discovered is a Video Logger where a history of actions is stored through the automated brew house. When something goes wrong, everything the technician does to fix the problem is recorded. Next time, it’s much easier to fix.

The Romance

While machines bring efficiency, some steps will never feasibly be automated or can only be automated to a degree.

Breweries need to carefully pick and choose what technology to invest in with long-term costs in mind, including maintenance.

Humans are a mainstay in the following three processes:

There’s another curious process we found that requires brewers’ special attention because it relies on seasonal trends.

Specialty Augmentations – Most existing brew houses aren’t built to process unique ingredients such as agave and pineapple, and require the breweries to make adaptations when a popular flavor catches on. New parts must be soldered on for keeping up with seasonal trends. Breweries take a risk when they decide to augment their brew house for new ingredients, hoping the trend will stick around past the season.

We noted that breweries with ingredients indigenous to their region will be more likely to augment their brew houses for local flavors. This is why beer lovers might notice some breweries specialize in pumpkin flavors but not grapefruit, despite both being very popular.

The Impact

Craft beer has its roots in microbreweries founded by hobbyists and small businesses.

For those less automated, the romance of brewing is a necessity tied to their success, as Luke with Evil Genius explained:

We don’t use heavy lifting machines because we’re small and a lot of the art of brewing is in the feeling. If you’re shipping out you definitely need machines to lift pallets.

When discussing the romance of brewing with James from Victory, the most automated craft brewery we met with, he shared a similar sentiment:

We just past our 20th anniversary, which is really exciting, but you’ll find that there aren’t as many ‘life-ies’ in breweries anymore. Brewers don’t feel as connected to the brands they make since the romance is lost with all the automation. What’s to stop them from moving out to California once they’ve got enough experience?

In the end, when fewer hands touch the product this leads to higher quality. Some romance must be sacrificed to scale out successfully, leading many craft breweries to implement automation as they grow.

The bottom line: When brewers compete locally, distribution is less of a problem and the romance remains fully intact.

Thanks to brewery automation, craft beer has become incredibly popular and has spurred highly competitive brews. Beer drinkers and breweries alike love consistent quality products.

This leaves the relationship between many brewers and their craft to be tumultuous, but there’s still opportunity for romance.

More about this article: We’d like to give special thanks to the King of Prussia Beer Outlet for introducing us to various brewery experts, Victory Brewing for inviting us to their new Parkesburg facility, and Sly Fox, Saint Benjamin, Free Will, Yards, and Evil Genius for offering us insight on how their facilities are affected by automation. Feel free to share and discuss how the romance of craft brewing has changed with the rise of machinery in the comments below!

Choosing a CMMS vendor is all about finding the right fit. Use our Vendor Comparison Guide to get an objective look at the top solutions.

Choosing a CMMS vendor is all about finding the right fit. Use our Vendor Comparison Guide to get an objective look at the top solutions.