Vendor:

Founded:

Headquarters:

Limble CMMS

2015

Lehi, UT USA

Customers:

Deployment Model:

Free Trial:

50,000+ users

Cloud

Yes

Limble CMMS At A Glance

Product Overview

Limble CMMS organizes, plans, tracks and simplifies a company’s maintenance operations by giving users the tools to automatically track work orders, schedule preventive maintenance (PM), receive external work requests, track asset history, manage inventories and generate reports.

Through its mobile app, users can view assigned work orders and PMs, and complete and log them while simultaneously doing the work. The mobile app notifies field users when new work is created and lets users start new work orders from the field, report issues using pictures and text, and research critical asset information while investigating an issue.

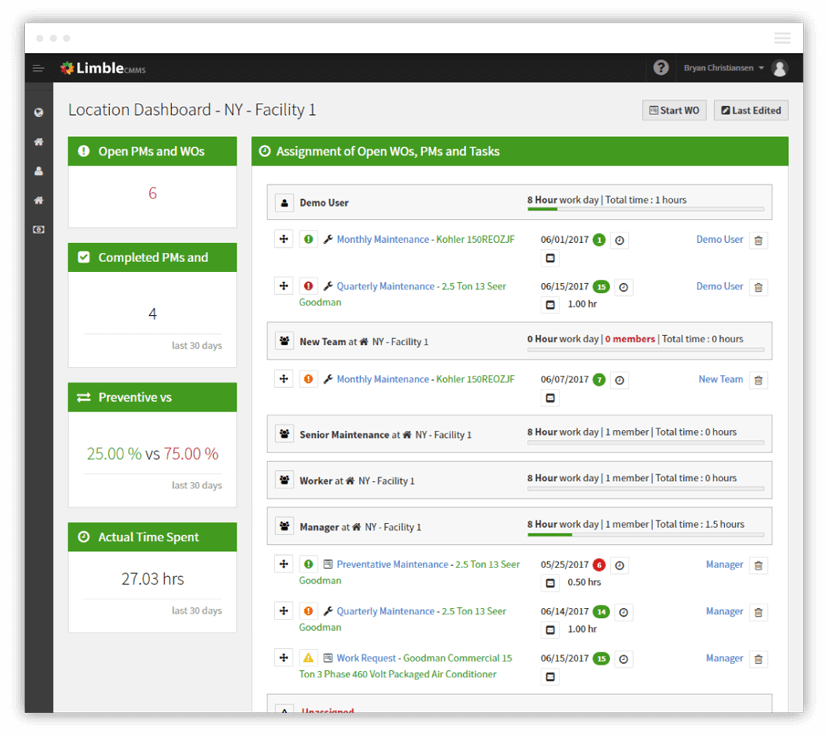

The user interface delivers a straightforward dashboard from which work orders, PMs, work history and more can be reviewed. Its left side-bar offers easy navigation through the features and settings.

Its overall functionality aims to extend an asset’s life, visualize the maintenance process based on gathered data, track work histories, improve accountability, and empower mobile and distributed team members,

Features

The features found in Limble CMMS include a Mobile Maintenance App, as well as modules that manage Work Orders, Preventative Maintenance, Asset Management, Work Requests, Reports and Dashboards, Parts/Inventory Management and Predictive Maintenance.

Mobile Maintenance App – This tool facilitates organization, communication, accountability and productivity among a user’s maintenance team. From any device, anywhere at anytime, users can view assigned work orders and PMs, start new ones, receive instant notifications regarding a work order, report problems using pictures and research critical asset information while diagnosing an issue.

Work Orders – Through this tool, maintenance team members get job instructions; automatic push and email notifications; and the ability to comment and attach pictures, attach invoices and required parts, record time spent, track downtime and request materials.

Preventive Maintenance – This module lets users automate PM scheduling, assuring the right work is delivered at the right time to the right technician. Set in a calendar platform, it sends push and email notices upon PM creation, renders views of all open and upcoming work and the priority of each, and automatically registers work completion into the asset’s maintenance log.

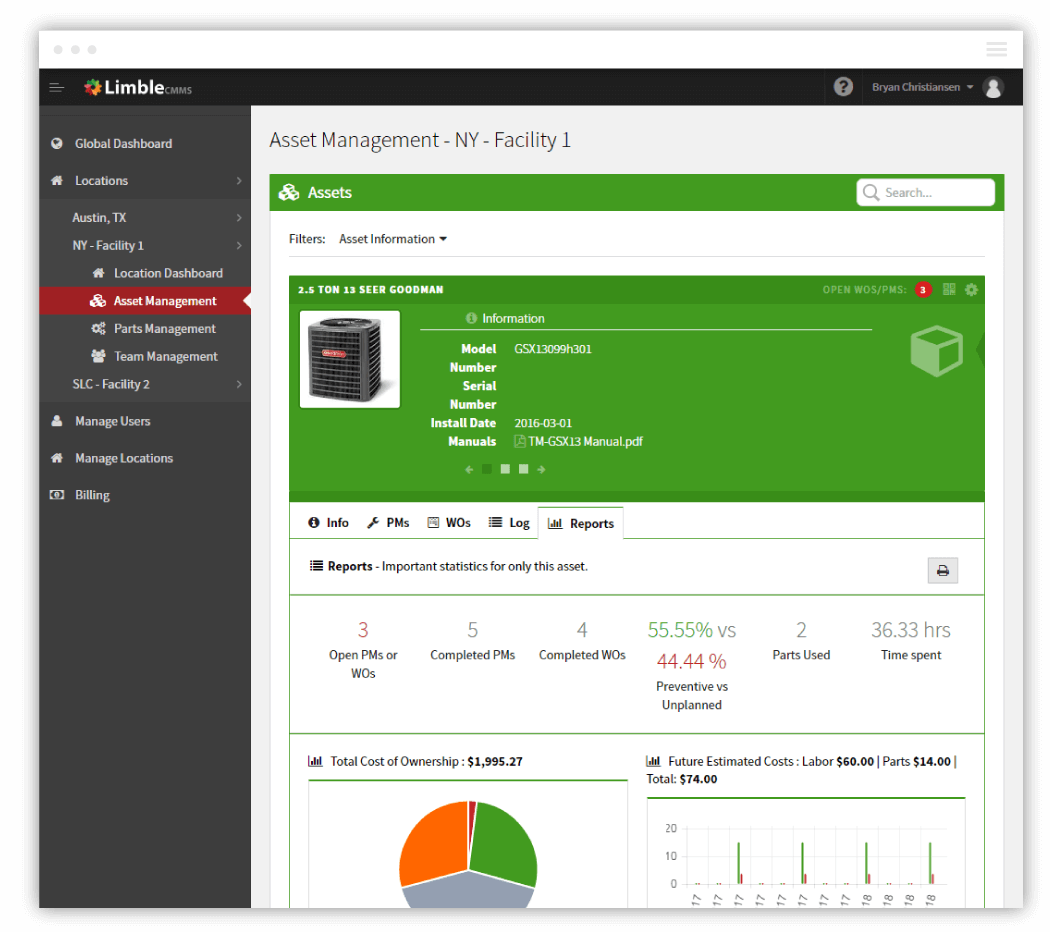

Asset Management – This feature and its wholly customizable fields enable users to track project location, make, model, manuals, pictures, mileage, hours run, meter reading and more. It sports a centralized asset card from which all details about that asset can be viewed, complete and detailed maintenance logs, real-time reporting, and barcode marking and reading for quick identification of an asset in the field.

Work Requests – This tool lets users report a problem by scanning a barcode, drafting a description and submitting it – without requiring a login. From any device anywhere, it automates CMMS login and push and email notifications (including letting work requester know when job is complete).

Reports and Dashboards – Users can view the status of and extract insight about ongoing maintenance operations. These tools provide data on work completion, schedule and costs, asset costs, average time to repair and time between failures, parts used for a repair and their costs, and more.

Parts/Inventory Management – Users get a full overview of parts with this feature. It automates parts tracking, renders parts log views, notifies team members if a part is or is not in stock, generates push and email notifications when part quantity dips below a set threshold, and lets users see if a part has been used (and by whom) or gone stale.

Predictive Maintenance – Limble uses a modular Internet of Things (IoT) sensor approach, where they send users pre-configured sensors that can simply be plugged in. Once activated, the sensor provides real-time detection of the equipment data, and sends instant alerts if the sensor levels reaches an unacceptable threshold and automatically triggers a maintenance task.

Target Market

Limble CMMS targets small, medium and large businesses in a myriad of industries, including manufacturers, equipment, agriculture, property, building, hospitality, churches, restaurants and fleet.

Below are several customers that have used Limble CMMS.

- UniLevel

- IHG

- Little Giant Ladder Systems

- Sommer MetalCraft

- FiberNet

- United Disposal

- Ken Garff Dealerships

- GracePoint Wesleyan Church

- Valley Salt Mine

- Regal Beloit

Download Now: The CMMS Buyer's Guide

Choosing an CMMS Solution is all about finding the right fit. Our report will walk you through the process and help you make a smart purchasing decision. Download Now

Choosing an CMMS Solution is all about finding the right fit. Our report will walk you through the process and help you make a smart purchasing decision. Download Now

Implementation/Integration

To implement Limble CMMS, a prospective customer needs only to visit Limble’s pricing page and click on “Start 30-day trial.” The program will download in minutes. Limble does not ask for credit card or other payment means for the free trial.

Once the software has been loaded and run, most customers will get fully up to speed on its performance and capabilities within a few weeks.

At implementation, Limble assigns to each customer an implementation specialist, who is available through email, phone or live chat. This specialist can help with on-boarding new users, system training and anything else a customer needs to attain full functionality with the CMMS.

Customer Service & Support

Limble customers have direct access to a dedicated CMMS adviser through email, phone or live chat at any time during business hours.

There are also embedded videos and guides for post-implementation training.

Pricing

Limble CMMS offers a free plan and three paid pricing plans (billed annually):

Basic – The Basic plan is free and comes with limited features, such as unlimited work orders with attached images, unlimited work requesters, real-time communication, up to four active recurring work orders, up to two work orders with attached procedures, one month of advanced analytics, unlimited work order exports, unlimited assets and custom fields, and work request photo capture and markup.

Standard – The Standard plan costs $28 per user, per month and adds on unlimited recurring work orders, up to three work orders with attached procedures, three months of advanced analytics, unlimited work requests, unlimited custom dashboards, asset/equipment downtime reporting, and the ability to start procedure on demand.

Premium+ – The Premium+ plan costs $69 per user, per month and includes all of the features of the Standard plan, plus unlimited work orders with attached procedures, unlimited advanced analytics, meter and threshold-based scheduling, parts inventory management, vendor and purchase order management, time and cost tracking, API, work request portal customization, Internet of Things (IoT) sensor integration and a dedicated customer success manager.

Enterprise – The Enterprise plan requires a custom quote. It adds on custom escalation notification, custom roles and approvals, advanced controls, multi-location tools and reporting, advanced integration, AI-powered duplicate checks, inventory cycle counts, custom budgets and 21 CFR compliance.

How Much Does A CMMS Cost?

Download our free report to compare pricing and cost info for 14 top CMMS solutions including IBM Maximo, Oracle, Upkeep, eMaint and more.Download NowShortcomings

Users report an occasional, infrequent glitch, but Limble customer support handles these bugs promptly. Some users note Limble has limited integration capability with third-party software. A recent upgrade provides a customer report generator, negating concerns reporting functionality was limited in earlier versions.

Screenshots

About

Originally motivated by a statistic from Reliable Plant Magazine that up to 80 percent of all CMMS implementations fail before bringing the desired ROI, Bryan Christianson and the gang at Limble set out to solve the problem. By 2015, Limble had built the first truly easy-to-use, mobile, modern CMMS that could be set up quickly, function intuitively and deliver ROI within a matter of weeks.

Download Comparison Guide